Belt Driven Vs Direct Drive Whole House Fan

Where on a belt drive fan the fan motor shaft has a pulley connected by a belt to a second pulley.

Belt driven vs direct drive whole house fan. I fantasized building a small shack outside my house and setting the attic fan in the shack and running a duct up to the attic and through the same vent as an attic fan. Directive drive are louder but i think that will be the way to go for my mom s house basing on the information that you shared. Direct drive models are the most do it yourself friendly because for most no attic joists need to be cut. The two bearings on direct drive fan motors which are 7 horsepower and larger are typically regreaseable.

With a belt drive the fan speed can be easily raised or lowered but there is belt and bearing maintenance to consider with a belt drive there are 2 additional bearings. Belt drive fans are quieter than direct but still noisy. There s also no belt residue and these fans cost less to maintain generally speaking because belts don t wear down and break. A well balanced direct drive is far quieter than belt.

It s incredibly hard to balance a belt and pulley system. Direct drive fans should be designed for acceptable bearing life. More often than not the maintenance cost of this kind of fan is also comparatively lower. When compared to belt drive fans which require belts sheaves and bushings direct drive is just plain simpler and maintenance folks tend to lean toward direct drive for daily maintenance.

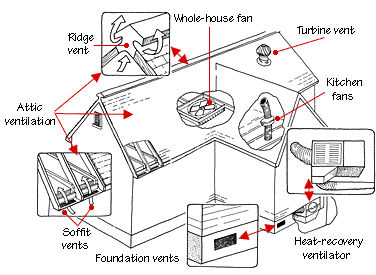

Sizing a whole house fan. Direct drive fans are more efficient than belt driven fans 80 vs 60 direct drive fans cost the same as belt driven fans belt driven fans challenge the filters very much because of dust coming from the belt that guy was not a direct drive fan supplier. Direct drive fans have no power transmission loss since the propeller is directly connected to the motor shaft. The second pulley is connected to a shaft that drives the fan propeller.

Most whole house fans are relatively easy to install. On a direct drive fan as implied by the name the fan propeller is connected directly to the shaft of the motor. Direct drive fans require fewer parts and thus usually less maintenance. This is because of the fact that the amount of friction is greatly reduced in case of this fan when the fan is operating.

It s balance or lack of balance actually which causes most of the noise. Belt drive whole house fans that use an integrated pulley system take longer to install but a belt drive unit provides for a smoother and quieter operation. Greater efficiency is the biggest pro of direct drive fan configurations. Unlike belt driven fans there s less energy loss because there s a reduced amount of friction as the fan operates.

Belt drive fans have two additional bearings. On both direct drive and belt drive fans the motor has two bearings.